Lead Screw Design and Types

- Lo Jm

- Jan 3, 2024

- 6 min read

A lead screw is a kind of mechanical linear actuator that converts rotational motion into linear motion. Its operation relies on the sliding of the screw shaft and the nut threads with no ball bearings between them. The screw shaft and the nut are directly moving against each other on a large contact area, so higher energy losses due to friction are produced. However, the designs of lead screw threads have evolved to minimize friction.

The lead screws are a cost-effective alternative to ball screws in low power and light to medium-duty applications. Since they have poor efficiency, their use is not advisable for continuous power transmission. Unlike ball screws, they operate silently with no vibration and have a more compact size. They are typically used as a kinematic pair (linkage) and actuation and positioning in equipment such as lathe machines, scanners, recorders, wire bonders, and disk drive testers. They are used to transmit forces in testing machines, presses, and screw jacks.

一,Lead Screw Design:

The components of a lead screw are the following:

Screw Shaft

The screw shaft is a cylindrical rod that has a single or series of grooves running helically around its length; this is referred to as the external thread.

Thread

The thread is the structure responsible for converting rotational motion into linear motion as the screw shaft and the nut slide with each other.

The lead screw nut is a cylindrical section that has an internal thread that matches the external thread of the screw shaft.

Lead screws may be operated in two possible ways. One mode of operation is either the screw shaft or the nut rotates and moves linearly while the other component is fixed. This mode is commonly seen in printers and helical pairs. The other mode of operation is either the screw shaft or the nut rotates but does not move linearly. This mode is commonly seen in presses and lathes.

The design aspects of lead screws are the following:

Major Diameter

The major diameter is the largest diameter of the thread. The major diameter of the screw shaft is the distance between two opposite crests, while the major diameter of the nut is the distance between two opposite roots.

Minor Diameter

The minor diameter is the smallest diameter of the thread. The minor diameter of the screw shaft is the distance between two opposite roots, while the minor diameter of the nut is the distance between two opposite crests.

Crest

A crest is the raised helical structure in an external thread (screw shaft) and the recessed helical structure in an internal thread (nut).

Root

A root is the recessed helical structure in an external thread (screw shaft) and the raised helical structure in an internal thread.

Thread Depth

The thread depth is the distance from the root to the crest, measured radially.

Flank

The flank is the surface that connects the root to the crest.

Pitch Diameter

The pitch diameter, or the effective diameter, lies concentrically and approximately halfway between the major and minor diameters. It is the diameter of the imaginary cylinder whose circumference intersects half of the thread pitch.

Pitch

The pitch is the axial distance between two adjacent threads measured parallel to the axis. It is equivalent to 1/number of threads per inch.

Lead

The lead is the linear distance traveled by the screw shaft or nut along its axis in one complete revolution (3600 rotation). As the lead increases, the linear speed also increases, but the load capacity of the lead screw decreases.

Thread Starts

The number of starts refers to the number of independent threads running around the length of the thread. The lead of a screw is determined by multiplying the number of independent threads by the pitch.

Most lead screws have one, two, or four starts. A single-start lead screw has a lead that is equivalent to its pitch. Multiple-start lead screws are used when higher speeds and higher load capacities are desired. The higher the number of starts, the longer the linear distance traveled for a single rotation. In double start lead screws, for example, the lead is equivalent to twice its pitch, which means that the axial distance covered by one rotation is two-pitch units.

Helix Angle

The helix angle is the angle formed between the helix of the thread and the line perpendicular to the axis of rotation. Generally, a lead screw with a higher helix angle has lesser frictional losses and therefore has higher efficiency. This is because the number of revolutions to rotate such a screw is lower than a screw with a lower helix angle for the same linear distance covered. However, it requires more torque to rotate the screw.

Lead Angle

The lead angle is the complementary angle of the helix angle. It is the angle formed between the helix of the thread and the line parallel to the axis of rotation.

Thread Angle

The thread angle is the angle formed between two adjacent threads.

Screw Handedness

Screw handedness refers to the direction in which the thread runs along the length of the screw. A lead screw may be right-handed or left-handed. In right-hand and left-hand screws, the thread runs around the screw length in a clockwise direction and counterclockwise direction respectively.

二 ,Types of Lead Screw Threads

The following are the types of lead screw threads based on their profile:

Square Thread

The square thread has its flanks at right angles to the axis of the screw. No radial or bursting pressure is acting on the nut since square threads have a 00-thread angle. Square threads have less resistance to motion and less friction.

Square threads are typically used in power transmission. Typical applications of square threads are in lathe machines and jackscrews. However, they are difficult and costly to manufacture. They are manufactured by using a single-point cutting tool. Their load capacity is also the lowest since the areas of the tooth at the crest and root are similar.

Acme Thread

The acme thread has a 290-thread angle. This modification of square threads was developed in the mid-1800s. Acme threads have a higher load capacity than square threads because the tooth has a wider base. Another advantage of this type is their low number of threads per inch, which increases the lead. The wear of the threads can be compensated. However, they are less efficient than square threads due to friction introduced by the thread angle.

The angled flanks of the acme threads allow them to be manufactured easier than square threads by a multi-point cutting tool. Typical applications of acme threads are in bench vices, clamps, valve stems, lathe machines, and linear actuators.

There are three types of acme thread: the General Purpose, the Centralizing, and the Stub acme threads. Both General Purpose and Centralizing acme threads have a depth thread equivalent to half of its pitch diameter. Centralizing acme threads have tighter tolerances between the external and internal threads to prevent wedging when a radial load is applied. The stub acme thread has a thread depth of less than half of its pitch while adapting the features of the General Purpose and the Centralizing acme threads.

The trapezoidal thread is similar to the acme thread, except that the thread angle is 300. It is manufactured in metric dimensions; that is why it is referred to as "metric lead screw" or "metric acme screw."

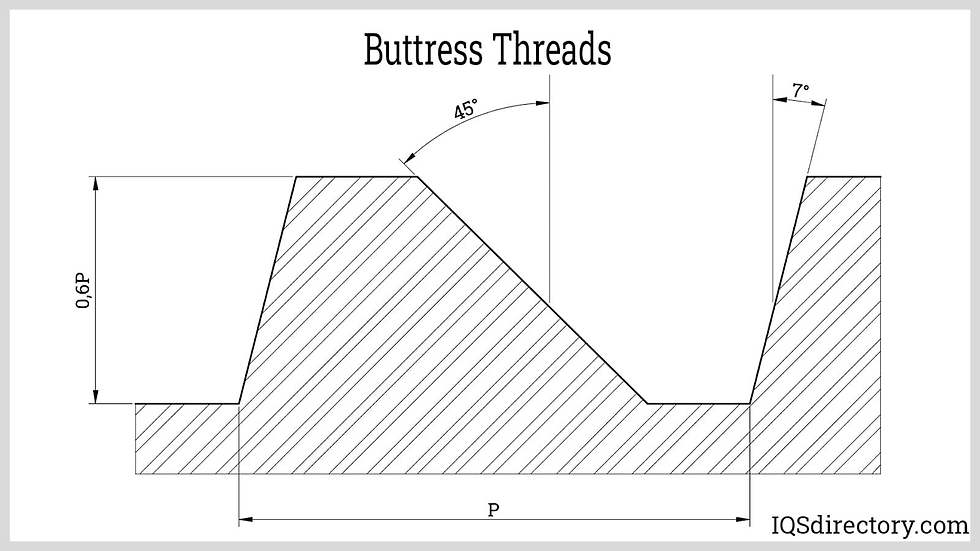

Buttress Thread

The buttress thread is designed to handle high axial loads and transmit power in one direction; the direction depends on the orientation of the weight-bearing and trailing flanks. The weight-bearing flank of a standard buttress thread makes a 70 slant while its trailing flank makes a 450-angle slant. The tooth of the buttress thread has a wider base, which gives the screw about twice the shear strength of the square thread. The efficiency is almost equal to the square thread due to its low frictional losses.

Buttress threads are used in large screw presses, jacks, vertical lifts, turning equipment, and milling equipment. However, it is only ideal for unidirectional thread application and performs poorly if the axial load is applied in the opposite direction.

The commonly used methods in manufacturing lead screws are the following:

Thread Rolling

In thread rolling, the metal rod (the blank material) is compressed between two roller dies containing a thread profile. The dies deform the surface of the blank after multiple passes; this transfers the thread profile to the workpiece. Thread rolling is a metal cold forming process; hence, the thread achieves higher strength and hardness. The products from thread rolling are "rolled threads".

Thread Whirling

In thread whirling, the metal rod is clamped in the whirling head and titled to achieve its desired helix angle. The whirling head rotates the rod at high speeds while pushing it slowly against a single cutting tool. Thread whirling enables the production of threads in only a single pass. It is capable of making deeper and more accurate threads. The products from thread whirling are "cut threads."

Comentários